Reflow soldering common problems maintenance program01

Date:

2023-05-06 08:26:47

1.Hot wire replacement

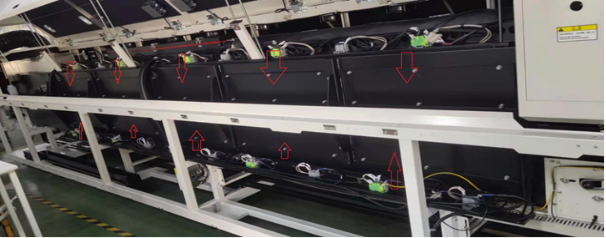

When the reflow welding equipment is in use, the temperature of a certain temperature zone of reflow welding cannot reach the set value, we need to check whether the heating wire is burned out (measure the resistance value of the heating wire), if it is burned out, we need to replace the spare parts, the method is as follows

01 When the device is powered off, open the rear cover behind the device and remove the cover of the heating wire to be replaced.

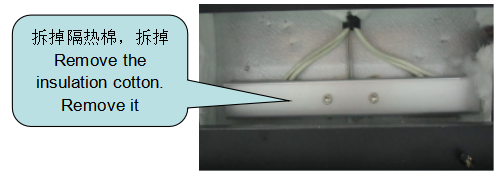

02.Remove the heat insulation cotton and remove the heating wire mounting plate.

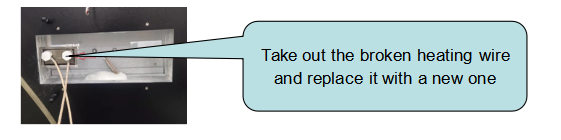

03.Take out the faulty heating wire, install the heating wire according to the original, replace the new heating wire and lock the screws according to the original lock.